INDUSTRIES

Industrial & Engineering Systems

Precision-engineered thermoformed and composite components built to perform in demanding industrial environments.

Windmill

Energy Systems

General Industrial Applications

Industry Overview

Engineered for High-Stress Industrial Environments.

Industrial and engineering systems operate under heat, pressure, vibration and continuous load.. which means every part must be stable, safe and long lasting.

Advanced plastics and composites outperform metal in corrosion resistance, weight reduction, forming flexibility and lifecycle value.. enabling better performance with fewer failures..

Clients get components that maintain structural integrity under extreme weather, rotating loads and round-the-clock usage.

WHAT BUYERS SOLVE HERE

Built to Eliminate Operational Weak Points

Reduce failures caused by corrosion, UV exposure and temperature fluctuations.

Replace heavy metal housings with lighter, more energy-efficient alternatives.

Improve system uptime with durable, long-life composite assemblies.

Accelerate engineering cycles with rapid prototyping and in-house tooling.

Where These Parts Are Used

Applications across Energy and Industrial Systems

- Windmill nacelle covers, cable trays, HVAC ducts and protective housings

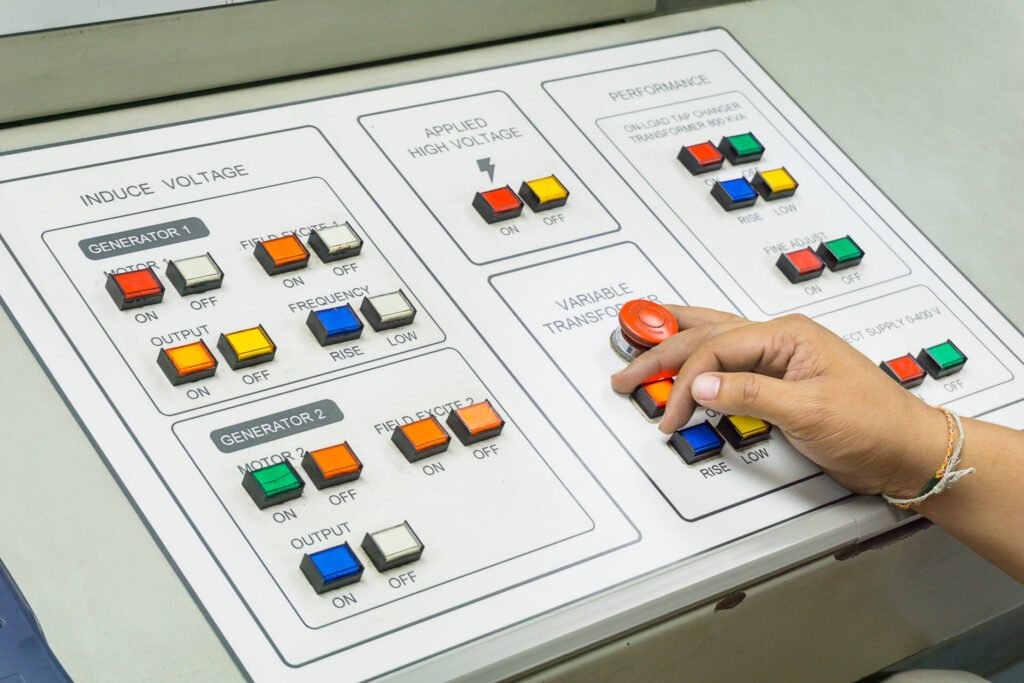

- Electrical control panel covers and enclosure systems

- Industrial machine guards, safety shields and structural panels

- Ventilation ducts, air-handling modules and flow-control assemblies

- Pump and motor covers, insulation housings and protective shrouds

- General industrial assemblies used in factories, processing units and utilities

Capabilities Mapped to Industrial Needs

Capabilities Designed for Load, Vibration and Weather

Each process is mapped to load-bearing requirements, weather conditions, vibration patterns and system operating cycles.

Lightweight, corrosion-free panels

Long-life structural and weather-resistant components

Precision composite parts for large assemblies

Faster design validation and custom engineering builds

Plug-ready systems for enclosures, ducts, and housings

PU coating, texturing, trimming, painting

Vacuum Forming & Thermoforming

Lightweight, corrosion-free panels

FRP & Hand Lay-Up

Long-life structural and weather-resistant components

RTM & Silicon Bagging

Precision composite parts for large assemblies

3D Printing & Prototyping

Faster design validation and custom engineering builds

Assembly & Bonding

Plug-ready systems for enclosures, ducts, and housings

Finishing & Value-Added Services

PU coating, texturing, trimming, painting

Proof of Reliability

Quality That Holds Under Pressure

ISO-certified manufacturing systems

Batch traceability and inspection protocols

Stress, load and environmental testing

Dimensional consistency across multiple runs

Stress, load and environmentavl testing

Why Engineering Teams Trust Us

Built for Precision, Reliability and Long Service Life Large-format moulding capacity, strict quality systems and decades of industry learning ensure your components work flawlessly across energy, industrial and engineering environments.

GET IN TOUCH

Get components designed for precision, stability and long-term industrial performance

Let’s build components that perform as hard as you do.