About Mega Fibre

Building Trust Through Precision & Performance

For more than three decades, Mega Fibre has been the engineering partner behind thousands of plastic and composite components trusted by India’s top OEMs. Our legacy is built on manufacturing excellence, disciplined processes, a commitment to deliver precision at scale.

OUR LEGACY

Mega Fibre began in 1990 as a small composite shop building FRP bodies for utility vehicles for Mahindra and Force Motors. We grew in an era when Indian OEMs needed partners who could match global quality expectations, execute consistently, protect sensitive programs with absolute confidentiality.

Over the years, we built the expertise to deliver complex components with precision. From supplying a 40-foot single piece FRP roof for Mercedes buses to developing 34 large-size plastic components for Volvo India in just 40 days, our growth has been driven by solving challenges that others could not.

Today, Mega Fibre stands as a multi-capability plastics and composites manufacturer trusted by automotive, construction equipment, industrial, healthcare leaders for quality, reliability, long-term support.

A 35-year journey shaped by engineering discipline and OEM trust

Precision-built components, trusted for over 35 years.

A timeline of progress, innovation, dependable delivery

1990

Mega Fibre is founded

Started as an FRP manufacturer supplying durable body parts and structural components for early utility vehicles. The company begins building its reputation for reliability and hands-on engineering.

1996

Expansion into plastics and forming technologies

Introduced thermoforming and vacuum forming to offer lightweight alternatives to metal and sheet moulding. Began supporting new OEM programs with more cost-efficient, scalable solutions.

2004

Major OEM partnerships established

Awarded long-term contracts by leading Indian automotive and construction equipment OEMs. Developed complex components that required precision forming, assembly, and finishing.

2009

In-house tooling division launched

Set up complete mould-making capabilities to gain full control over development, reduce lead times, and improve part consistency across batches. This becomes a major competitive strength.

2014

Large-format capabilities added

Installed one of India’s largest vacuum forming machines (2.8 m x 1.7 m), enabling single-piece, large-size panels for automotive and industrial applications.

2021

Advanced composites and automated processes adopted

Added silicon bagging, RTM, robotic trimming, ultrasonic welding, PU painting, and modern finishing lines to support complex geometries, faster turnaround, and export-grade quality.

2024

Next-generation engineering expansion

Introduced 3D printing, design-for-manufacturing support, and digital production controls to help OEMs rapidly prototype, validate, and scale parts with confidence.

- 1886 ●

- 1888

- 2000

Mega Fibre is founded

Started as an FRP manufacturer supplying durable body parts and structural components for early utility vehicles. The company begins building its reputation for reliability and hands-on engineering. .

Expansion into plastics and forming technologies

Introduced thermoforming and vacuum forming to offer lightweight alternatives to metal and sheet moulding. Began supporting new OEM programs with more cost-efficient, scalable solutions.

Major OEM partnerships established

Awarded long-term contracts by leading Indian automotive and construction equipment OEMs. Developed complex components that required precision forming, assembly and finishing.

In-house tooling division launched

Set up complete mould-making capabilities to gain full control over development, reduce lead times and improve part consistency across batches. This becomes a major competitive strength.

Large-format capabilities added

Installed one of India’s largest vacuum forming machines (2.8 m x 1.7 m), enabling single-piece, large-size panels for automotive and industrial applications.

Advanced composites and automated processes adopted

Added silicon bagging, RTM, robotic trimming, ultrasonic welding, PU painting and modern finishing lines to support complex geometries, faster turnaround and export-grade quality.

Next-generation engineering expansion

Introduced 3D printing, design-for-manufacturing support and digital production controls to help OEMs rapidly prototype, validate and scale parts with confidence.

From a local start to a national leader.

Who we are

Mega Fibre combines disciplined engineering, strong material understanding, deep process control to create components that perform reliably in demanding environments. We build products that help OEMs reduce weight, improve durability, enhance aesthetics, achieve better lifecycle performance.

Our manufacturing ecosystem spans vacuum forming, FRP lay-up, RTM, silicon bagging, machining, finishing, assembly, 3D printing. Every part is produced with documented controls, traceability, rigorous quality standards to ensure consistency at every stage.

Engineering That Delivers Beyond Expectations

Who we are

Mega Fibre combines disciplined engineering, strong material understanding, deep process control to create components that perform reliably in demanding environments. We build products that help OEMs reduce weight, improve durability, enhance aesthetics, achieve better lifecycle performance.

Our manufacturing ecosystem spans vacuum forming, FRP lay-up, RTM, silicon bagging, machining, finishing, assembly, 3D printing. Every part is produced with documented controls, traceability, rigorous quality standards to ensure consistency at every stage.

Engineering That Delivers Beyond Expectations

What Drives Us

Our Core Values

These principles guide everything we do, from design to delivery.

Integrity in every commitment

We honour timelines, protect data, stand by every part we ship.

Partnership built on trust

OEM programs depend on reliability. We build relationships that last decades.

Precision as a discipline

From mould building to finishing, accuracy and repeatability drive our culture.

Continuous improvement

We invest in better tooling, processes, systems to deliver dependable output.

Competitive Advantages

Why Manufacturers Choose Mega Fibre

Reasons OEMs trust us for long-running, high-dependency programs.

In-house tooling capability

Complete control over moulds, faster development cycles, stable production.

Large-format manufacturing

India’s largest vacuum forming bed size (2.8 m x 1.7 m) enables single piece, large surface components.

Global quality execution

Recognised as a “Global One Quality” supplier to JCB and a global supplier to Philips healthcare.

Multi-process expertise

Vacuum forming, FRP lay-up, RTM, silicon bagging, PU painting, robotic trimming, ultrasonic welding, more.

Cost efficient and scalable

Ideal for prototyping, medium volume, large part development without heavy tooling cost.

Reliable Delivery

Decades of long-term contracts backed by secrecy agreements and consistent on-time execution.

OUR CAPABILITIES

Built for Precision. Designed for Scale.

From design to delivery, complete control under one roof.

Vacuum Forming

Replace metal hassle with lighter, faster components.

Heavy metal parts slow production and increase cost. Vacuum-formed plastics solve that with strength, precision, repeatability for large-format applications.

3D Printing & Prototyping

Validate before you invest.

Unverified designs drain time and money in tooling. Rapid 3D prototyping brings your concepts to life faster and helps catch issues before full-scale production.

Fiber Reinforced Composites

When durability matters more than decoration.

In tough environments, parts fail when they’re not built right. FRP composites deliver rugged performance with smooth finishes built to handle daily abuse.

RTM & Silicon Bagging

Consistency where precision cannot fail.

Complex parts often lose strength due to uneven curing or weak moulds. RTM and silicon bagging ensure dimensional stability and surface quality every time.

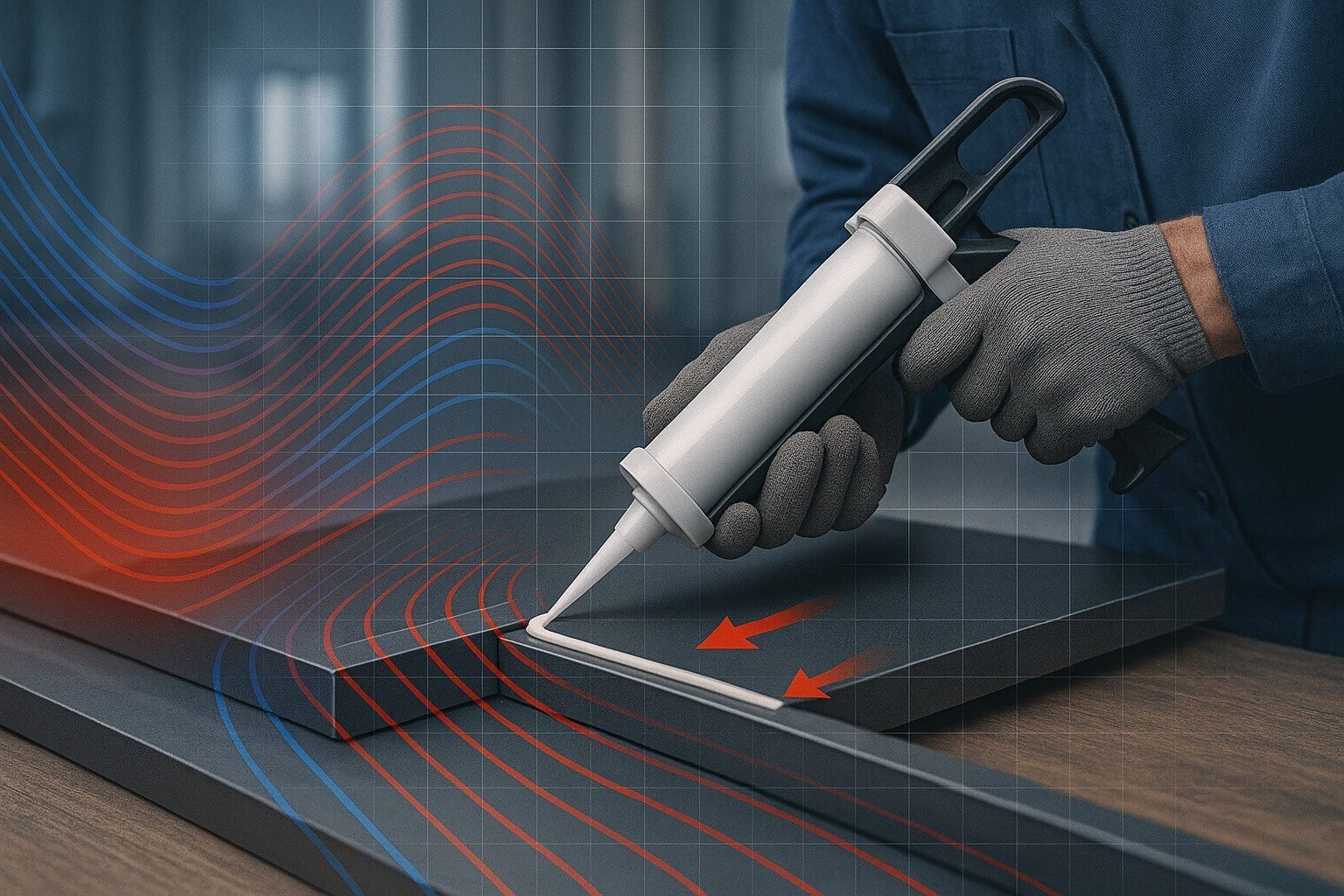

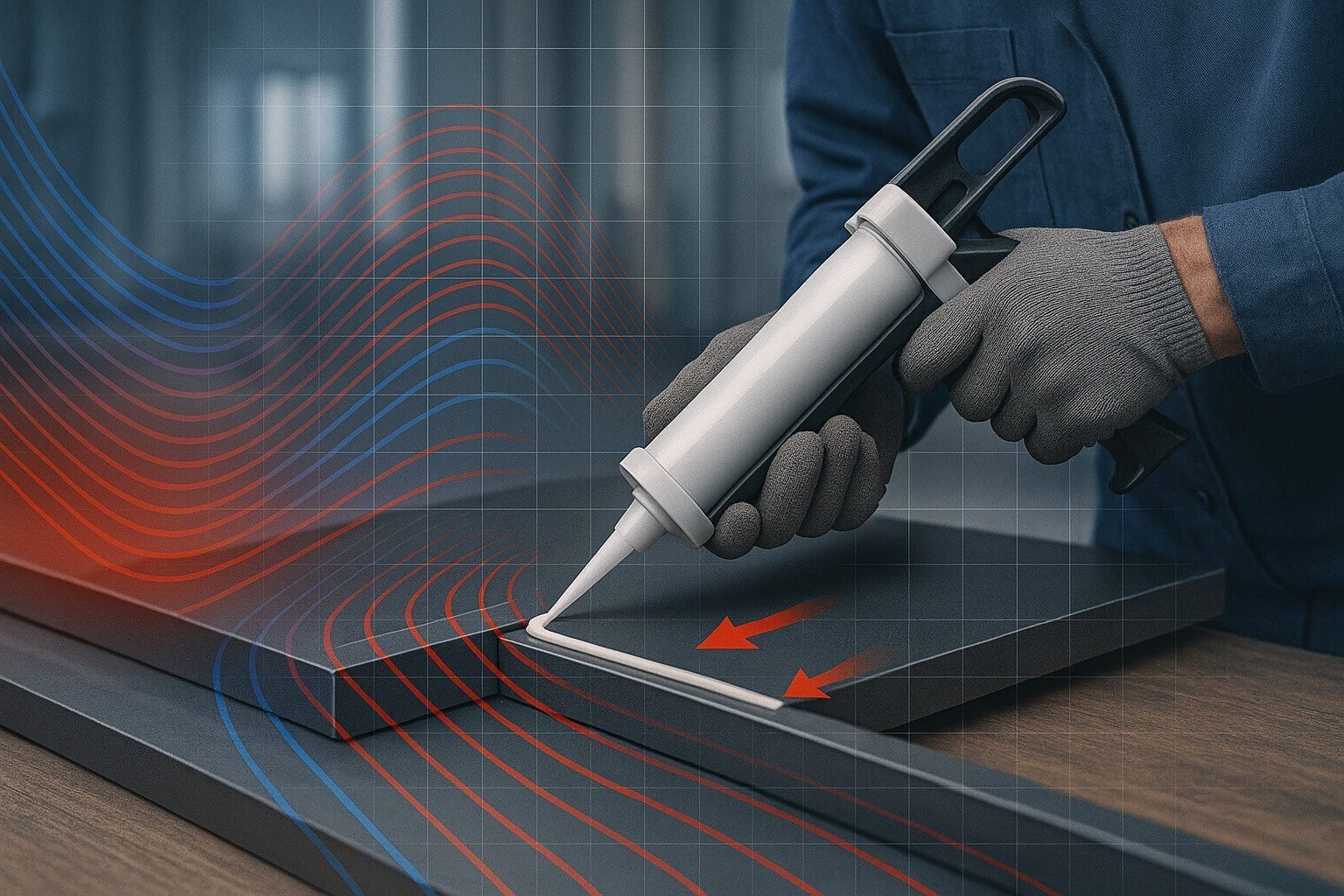

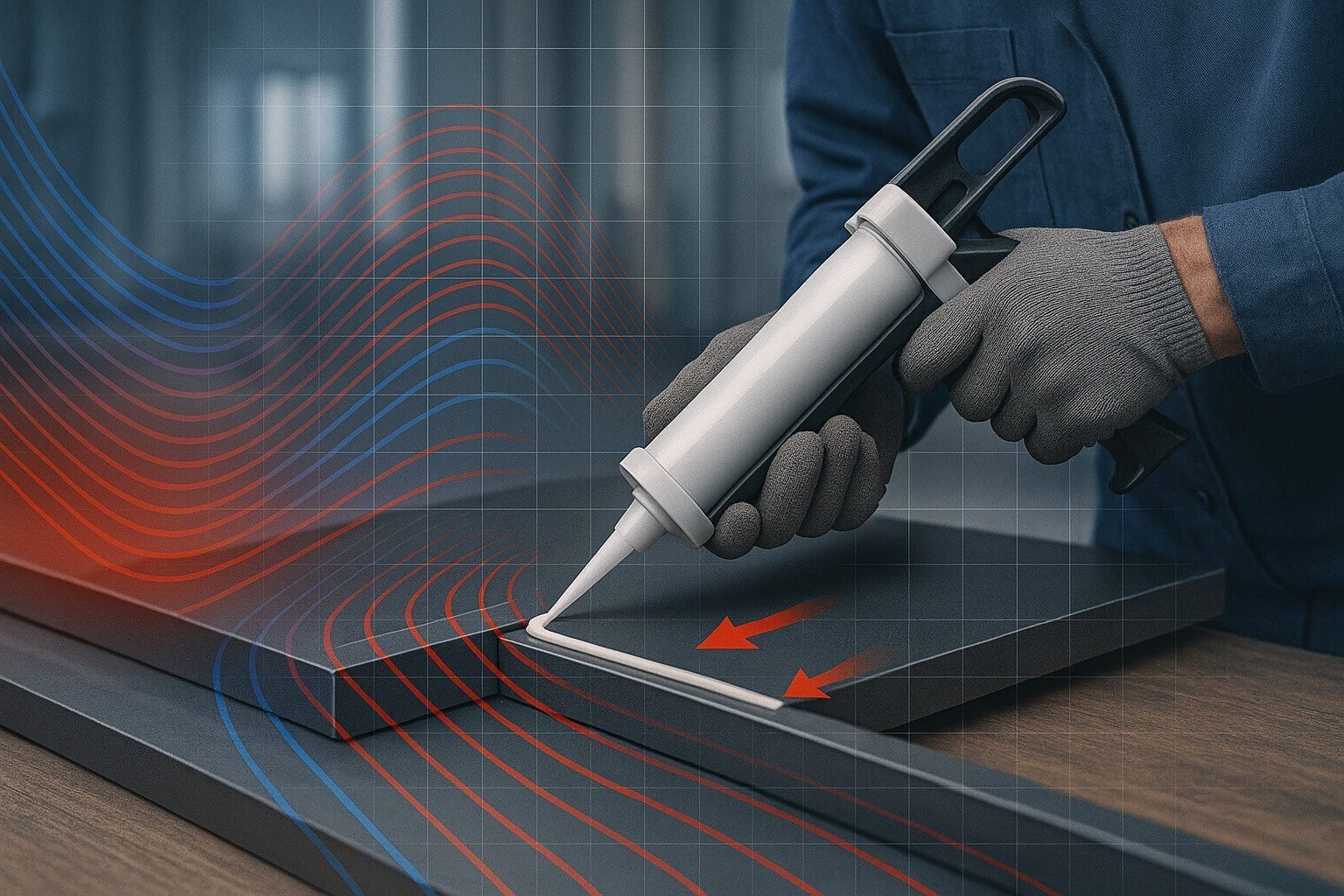

Assembly & Bonding

When every joint carries your reputation.

Weak bonding leads to costly breakdowns. Controlled assembly methods ensure your components stay strong under pressure and deliver dependable performance.

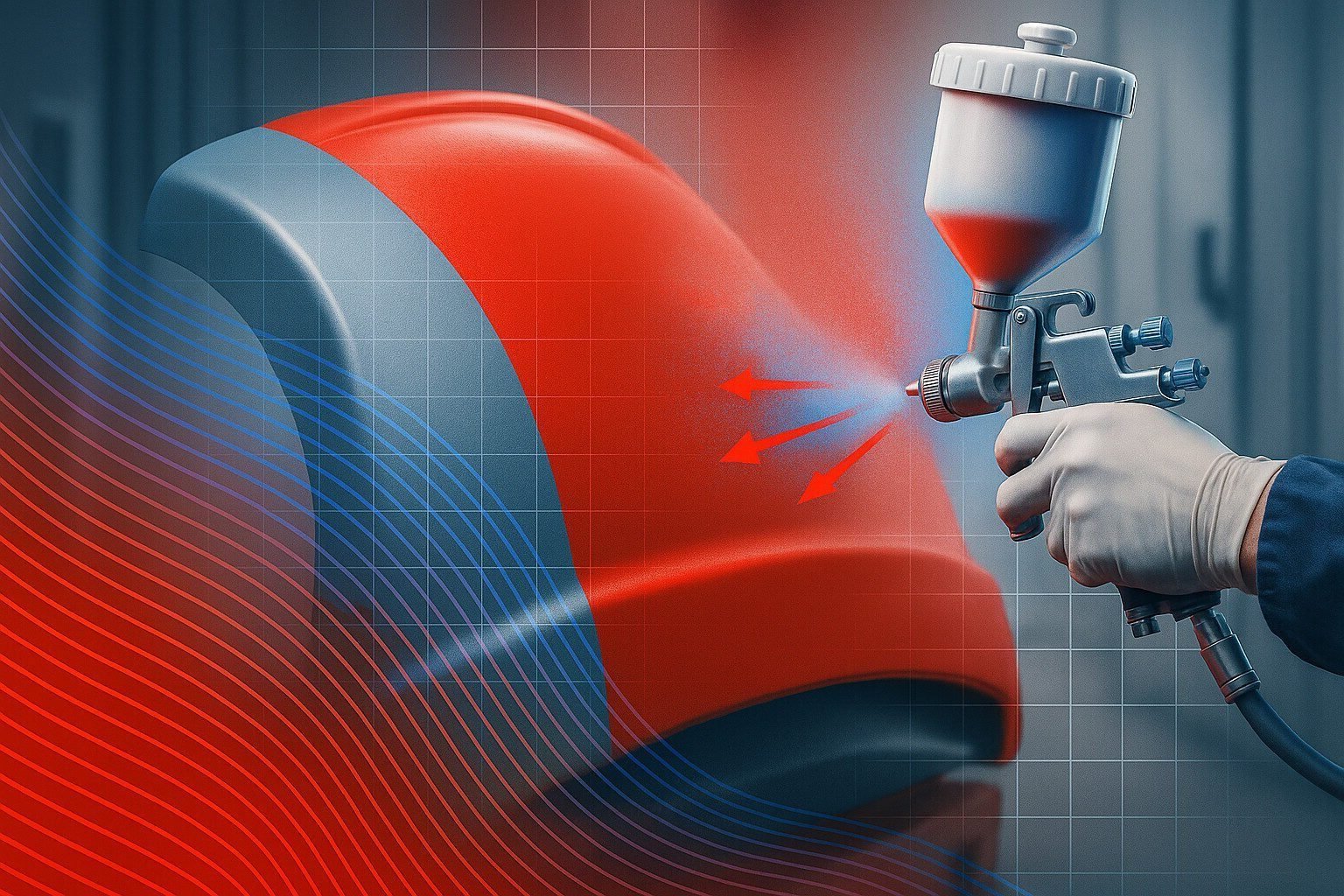

Finishing & Value-Added Services

Because good products deserve great presentation.

Finishing flaws cost trust. With precision surface treatments and coatings, every part looks consistent, professional, ready for delivery.

INDUSTRIES WE SERVE

Diverse applications across sectors

Mega Fibre supports manufacturers across automotive, construction equipment, industrial systems, healthcare equipment, kiosks, defence applications, general engineering. Our components function in environments where strength, stability, repeatability are non-negotiable.

Automotive & Electric Mobility

Automotive

EV Vehicles

Bus

Thermoformed and composite parts for passengers, commercial, and electric vehicle – dashboards, panels, enclosures, and trims.

Construction & Heavy Equipment

Construction Equipment

Machine Covers

Material Handling

Lift & Elevator

Durable FRP and plastic components for off-road, industrial, and lifting machinery that demand high impact and wear ressistance.

Industrial & Engineering Systems

Windmill

General Industrial Applications

Precision-molded components and enclosures used in industrial machinery, renewable energy and control system.

Healthcare & Equipment Manufacturing

Medical Equipment

Clean, chemical-resistant plastic housings and enclosures for medical and laboratory devices, built to meet strict hygiene and performance standards.

Infrastructure & Utilities

Cabin / Toilet

Agriculture

Pre-fabricated modules, kiosks, and functional components used in sanitation, agricultural ,machinery, and field installations.

Our Expertise

Engineering Excellence in Every Project

Years of Experience

Decades of manufacturing plastic and composite parts for complex OEM requirements.

Multiple core technologies

Decades of manufacturing plastic and composite parts for complex OEM requirements.

Commitment to Excellence

Driven by precision, discipline, a continuous focus on quality.

Our Expertise

Engineering Excellence in Every Project

Years of Experience

Decades of manufacturing plastic and composite parts for complex OEM requirements.

Multiple core technologies

Vacuum forming, FRP lay-up, RTM, silicon bagging, CNC/robotic trimming, PU painting, and 3D printing.

Commitment to Excellence

Driven by precision, discipline, and a continuous focus on quality.

GET IN TOUCH

Your Next Reliable Partner in Plastics & Composites

Whether you need lightweight structures, aesthetically refined panels, durable housings, or complete assemblies, Mega Fibre is ready to support your next program with precision and dependable quality.

BOOOK A FREE CONSULTATION

Your Next Reliable Partner in Plastics & Composites

Let’s build components that perform as hard as you do.

1986

1986

1986

1986

1986

Mega Fibre is established

From faster production to parts that outlast the machines, we help OEMs move from concept to market with speed, consistency, and confidence.

Mega Fibre is established

From faster production to parts that outlast the machines, we help OEMs move from concept to market with speed, consistency, and confidence.